MANUFACTURING OF OPAL STONE

Problems Facing By The Customers

As, The online market of gemstones are becoming increasingly popular day by day, some market sparrows are trying to cheat and steal the hard earned money from the people. They provide them fake gemstones on various selling platforms with fake certificates in very cheap prices.

They are getting very confused that how can a precious natural gemstone comes under 300 or 500 Rs per Carat or even more less and other genuine sellers are selling in very high price as compared to previous one. Those cheap and synthetic opal gemstone does not work at all as per astrology. It results in decreasing the trust and belief of customer on Opal. Its our duty to maintain that belief that the Opal must worn for solving the people’s problems and let them live a happy life with fulfilled desires.

Our Opal Manufacturing Process

Mining

Our Company ‘Aakarshan Gemstones Private Limited’ has a mining contract in South Australia Coober Pedy mines. Our highly experienced miners mines opal rough from the deep crust of mother Earth who are into the mining field in Australia from the several decades. They extract high quality rough from the mines and get the container ready for us to import it to India throughout the year.

Importing

Our company specializes in the importing the Opal Rough from Australia to India. We ensure that the Opal Rough is safely stored in our well maintained stock houses.

Selection of Rough

The quality team carefully sorts the Opal rough into different parts and stores them in separate containers. We reserve one set of container for big size fire opal stones, which are sized from 4 carats and used in ring by various Jewelry Manufacturers & Jewelry Designers. The other set of containers holds Calibrated MM small sizes in White fire from opaque to semi translucent quality and Crystal fire from semi translucent to transparent quality. The leading jewelry designers and Manufacturers regularly buy these calibrated opals for setting in various pieces of gemstone jewelry.

Cutting

The cutting process of an opal gemstone is a scrupulous procedure that involves several steps. First, Our skilled team examines the rough opal carefully to determine the best way to cut and shape it. Then, the team uses specialized tools to carefully remove any unwanted portions or impurities of the stone. The process includes grinding and shaping the opal to achieve the desired final shape and size.

Polishing

Opal stones are polished to enhance their natural beauty and luster. This process involves carefully polishing of the opal on various grinding wheels having different surface roughness value and make the opal surface superfine slippery from all sides. Our skilled craftsmanship are able to bring out the true brilliance of the opal, transforming it into a stunning gemstone with multi color eye catching hues. With precision and expertise, the polishing of an opal stone requires meticulous attention to detail, ensuring that both the sides reflect play of color in the most captivating way.

Finishing

The finishing of an opal stone is a critical process that requires expertise and precision. It involves carefully finishing with the specific polishing compounds naturally and enhancing the natural beauty of the stone. The goal is to create a smooth and flawless surface while bringing out the vibrant colors and unique patterns that make opals so mesmerizing. This delicate work skilled craftsmen who understand the characteristics of opals and have mastered the techniques necessary for achieving a high-quality finish. With their meticulous attention to detail, these professionals ensure that each opal stone reaches its full potential, ready to be cherished by its owner.

Quality Inspection

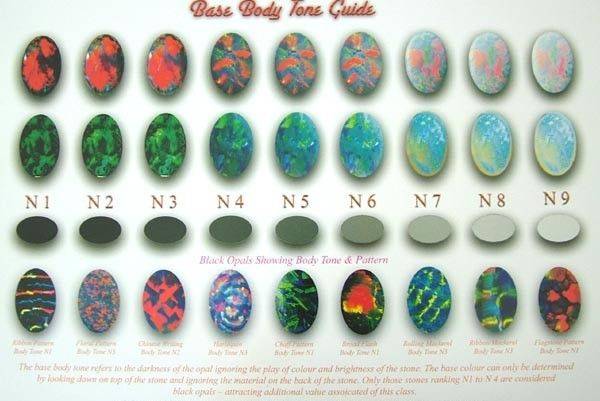

Our Qualified gemologists team diligently examine each opal stone for any flaws or impurities, that may affect its overall quality, sorting based on stone's color, clarity, any inflorescence present, and carat weight. The goal of this inspection is to provide customers with the highest standard of opal stones that meet their expectations and establish trust in the industry. Ultimately, by conducting stringent quality inspections, we can assure the superior quality of our opal stones to our valued customers and deliver the opal to our valuable clients with full of confidence.

Grading and Certification

Our team then grades the finished Australian Opal stones and make proper pricing based on stone's color, clarity, any inflorescence present, and carat weight and certification by the recognized lab. We are the member of various independent gemstone laboratories and have the authority to issue a certificate of authenticity that verifies its quality and provides essential information about its characteristics. This certification process helps maintain transparency in the opal market and ensures that buyers can make informed decisions when purchasing these beautiful gemstones.

Packaging

The packaging of an opal stone is an essential aspect of ensuring its safe and secure transport and presentation to customers. When packaging an opal stone, We use the materials that will protect the stone from any potential damage or scratches during transit. This includes using cushioning materials such as foam, velvet, bubble wrapping of the main opal box to prevent any impact or friction that could cause harm to the stone.. We understand the value and delicacy of these precious gemstones, which is why we take every precaution to ensure their safe delivery. You can trust us to handle your opal stones with professionalism and expertise in our packaging services.